Isovolta CERAPREG – innovative high-temperature material revolutionizes the market.

Industries of the future with strong potential for development

An innovative material that withstands high temperatures while remaining light in weight is sought after in many industries. The materials currently available on the market are not only expensive, but only meet the highly complex and specific requirements of the clients in the rarest of cases. The aeronautics, aerospace and space industries, but also all related industries such as electro-mobility, long for innovative material developments which are, on the one hand, temperature resistant and on the other hand, weight-optimized.

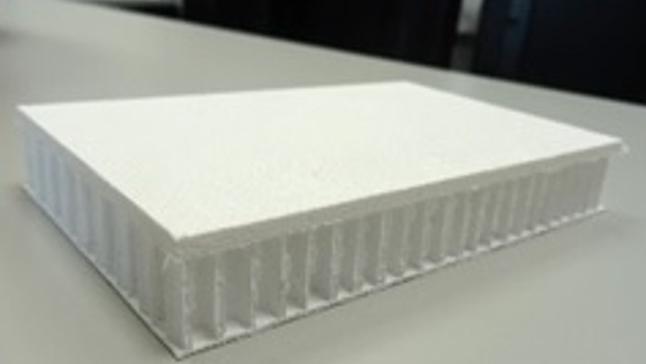

A market revolution named CERAPREG

With the high-performance silicate-ceramic mixture CERAPREG, ISOVOLTA Group, as the international leading manufacturer of electric insulation materials, technical laminates and composite materials, brings a unique material to the market which enables far-reaching new developments in various industries and consequently is a true game changer in aeronautics, aerospace, defence and electro-mobility. The material, above all, scores points with a wide spectrum of characteristics which leave the supposed competing products on the market behind entirely:

Durability: The innovative material made of silicate and ceramic withstands a mechanical load of 900°C, is resistant to temperature change and quasi-ductile. Within this temperature range, CERAPREG is focusing to replace INCONEL and titanium for certain applications.

Load capacity: As a result of the glazing process the porous material not only becomes airtight, but also remains thermally and mechanically stable. It acts thermally and electrically insulating.

Customizable: The design is either rolling stock (prepeg) or custom-built depending on the customer specifications.

Drape ability: Upon request the material can be shaped into any three-dimensional shape without loss to the material characteristics. There is no risk of flaking.

Weight reduction: A reduction in weight of up to 40% as compared to current non-ceramic options is possible as a result of the new material.

Shelf-life: CERAPREG can be stored with low cost - storage does not need to take place in a specific thermal environment.

Free trade: CERAPREG is not subject to the International Traffic in Arms Regulations, therefore export and re-export are unproblematic.

Attractive price: CERAPREG meets the highest requirements of the market as a high-temperature material and is unrivalled not only in performance but also in price.

New opportunities for aeronautics, aerospace, Space and electro-mobility

Everywhere where reliable heat insulation and a significant reduction in weight are crucial, CERAPREG brings the decisive advantage.

Exhaust pipes for drones or heatshields for propulsion systems, for example, present precisely these material requirements. In the automotive industry one is also faced with the challenge of further developing the performance of exhaust systems or battery box. Also in the armament and space sectors CERAPREG offers totally new opportunities for innovative compound materials for components and composite parts. The aeronautics industry can exploit the many advantages of CERAPREG in turbine construction, among other things.

Know-how sensitive industries

Highly specialized technology know-how and, above all, sovereignty over proprietary in-house developments, processes and data are important arguments for the use of CERAPREG. The good workability of this material makes it possible for both design and construction features to remain in the hands of the clients and ensures that the advanced knowledge of technology and industry leaders are sustainably guaranteed within one’s own company.